In vehicle design, especially for industrially used utility vehicles and special-purpose vehicles, robustness and durability of components often plays a crucial role within hydraulic systems. Under extreme conditions, every minute of availability with full capacity often counts – downtimes such as unplanned failure of machines frequently have serious economic implications. Unwanted loss of hydraulic oil also potentially results in substantial hazards for people, machines and the environment.

The companies in the STAUFF Group offer manufacturers of utility vehicles and special-purpose vehicles as well as their suppliers, sub-suppliers and service providers an extensive range of original STAUFF products, some of which were specially developed for these complex applications or adapted and optimised continuously.

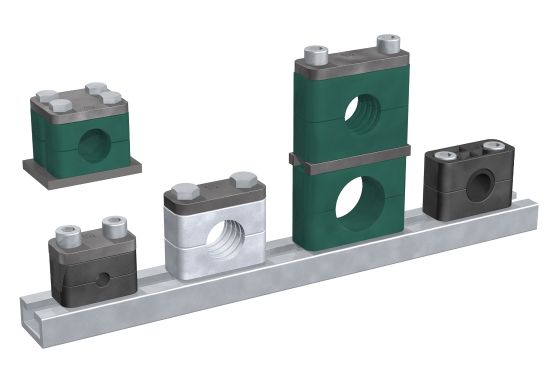

The portfolio includes hydraulic line components such as tube clamps and hose clamps, tube connectors including powerful assembly machines, flanges, hose fittings and couplings as well as filters, measuring equipment and other accessories for tank, container, drive unit and gearbox manufacturing for mobile hydraulics. These products from in-house development and manufacturing can be supplied all over the world at competitive prices and with a high level of availability from stock. STAUFF branches and a close network of authorised sales and system partners provide often unrivalled fast deliveries – precisely to any location worldwide.

The range is completed by countless special variants and system solutions, which are implemented based on customer requirements or in-house developments.

In addition to a long service life, optimum performance and easy application and assembly, STAUFF products particularly impress with the following features, which are particularly important for OEMs in the field of vehicle manufacturing:

- Robust, particularly impact-resistant design that resists even the strongest mechanical strains

- High resistance to environmental factors such as extreme temperatures and temperature fluctuations, humidity, UV and ozone

- Compact, space-saving and lightweight design which contributes to weight optimisation and lowering of the energy consumption

- Distinct vibration resistance, leak-proof design and tightness

- High resistance to static operating pressures of often more than 400 bar and permanent resistance to dynamically changing pressure loads, pressure surges and pressure peaks

STAUFF products for use within hydraulic lines are increasingly being developed with a uniform, coordinated quality and design. A large part of the range manufactured from steel features the high-grade STAUFF zinc/nickel finish. This ensures reliable corrosion protection which – even after transport, processing and assembly of the components – far exceeds the previous market standards, while also meeting all currently applicable legal requirements. The high-quality appearance supports the positive overall impression of the machines.

The product range is completed with a large spectrum of possible additional services which create measurable added value for customers, such as in the areas of application consulting, configuration, optimisation, assembly and kitting as well as customised labelling and packaging. You can also contact STAUFF about individually tailored supply models for optimising material flow, from stockpiling of customised items and Kanban logistics to just-in-time delivery straight to customers' assembly lines.

With the STAUFF Line concept, STAUFF offers mechanical engineering companies and line builders delivery of individual components for original equipment, as well as the option of procuring individually tailored hydraulic lines, assembled ready for installation, and complex line systems from connection to connection.

As a true one-stop supplier, the company allows customer to gain cost advantages in procurement by reducing the number of suppliers, bundling orders and shipments, reducing stock for individual items, reducing assembly times and increasing assembly reliability by avoiding assembly errors.

STAUFF products are not only ideal for OEM use, though. They are also a convincing solution for the maintenance, repair, overhaul and servicing of lifting and conveying equipment.

Increase the economic efficiency and performance of your utility vehicles and special-purpose vehicles with fluid technology components, systems and added-value services from STAUFF. Let us convince you.

Typical areas of application for STAUFF products

An example for utility vehicles and special-purpose vehicles in which STAUFF hydraulic components are typically already used as original equipment by the OEM (original equipment manufacturer). Other areas of application are low loaders, self-propelled modular transporters (SPMT), heavy-duty transport vehicles for locomotives, goods wagons and the transport of ships and ship segments at shipyards, for the aerospace industry and the transport of rotor blades, nacelles and tower segments in the wind energy industry, slab transporters and slag transporters for the steel industry as well as a large number of other utility vehicles, special-purpose vehicles and custom vehicles.

Top Selection of STAUFF Line Components

Selection of most relevant products and product categories for Utility and Special Vehicles

Top Selection of STAUFF System and Reservoir Components

Selection of most relevant products and product categories for Utility and Special Vehicles