STAUFF SPG-DIGI digital pressure gauges measure and display pressure up to 1000 bar with an accuracy of 0.5%. Designed for hydraulic systems (oils, lubricants, water), they provide current, minimum and maximum values. Available individually or in kits, these robust, reliable and easy-to-use tools.

STAUFF France x CTA Technologies

Innovative collaboration for industry

About CTA Technologies

CTA Technologies (Conseils Techniques en Assemblage) is a company specialising in innovative industrial assembly solutions, combining expertise and performance. Backed by proven know-how and a network of recognised partners, CTA Technologies helps its customers to optimise their industrial processes.

We were present on Stand Z715 (Hall 7000) of CTA Technologies at the SEPEM trade fair

Technical collaboration at the heart of innovation

The collaboration between STAUFF France and CTA Technologies highlights a common approach: to offer industry professionals innovative solutions that respond to concrete maintenance and optimisation challenges. Among the products of this partnership, the STAUFF PT-RF reader stands out as a revolutionary tool for managing hydraulic accumulators. Although designed by STAUFF, this product is now resold by CTA Technologies, which passes on its expertise in the field to its customers.

An Innovative Product Distributed by CTA Technologies

The STAUFF PT-RF reader is an advanced technology with wireless pressure sensors incorporating RFID chips. This solution, developed by STAUFF and adopted by CTA Technologies for its customers, brings tangible benefits:

- Simplified accessibility: the sensors are repositioned at man-height, making them easy and safe to read.

- Accurate data: the sensors guarantee reliable measurements without invasive intervention, thus reducing the risks associated with the operation.

- Reduced nitrogen losses: unlike conventional methods, this solution avoids unnecessary purging during pressure controls.

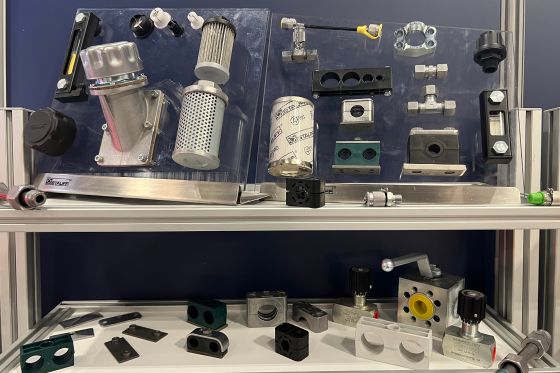

Discover the other STAUFF products distributed by CTA Technologies

STAUFF Hand-Held Hydraulic Testers PPC measure temperature, pressure, flow and power in hydraulic and pneumatic systems. They enable data to be analysed, stored and processed for monitoring, diagnosis and maintenance.

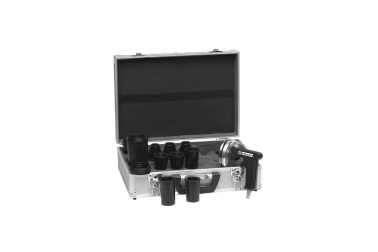

The STAUFF Clean includes a special air gun and a wide range of specially shaped plastic nozzles. It uses compressed air in the 6-8 bar range to propel a foam projectile through the plastic nozzle into the pipe to be cleaned. This method is not only safe and environmentally friendly - the operating principle is simple and correct operation can be learned quickly. STAUFF Clean is available individually or in various sets.

STAUFF Form EVO is the latest generation of tube forming system, renowned for its simplicity, safety and reliability. Designed for steel and stainless steel tubes (6 to 42 mm), it offers increased efficiency and versatility thanks to continuous optimisation. Ideal for accurate, repeatable metric connections, it incorporates a cloud module for customised parameters on demand.

The PT-RF series of STAUFF pressure transmitters provides an alternative solution for universal pressure measurement in fluid technology applications, and is aimed at operators, maintenance and repair personnel, as well as original equipment manufacturers. The benefits of using the new technology for operators, maintenance staff and technicians are clear: measurements can be carried out very easily, without extensive training and in a matter of seconds, at the touch of a button, and then reliably documented.