In cooperation with PROTIQ, one of the market leaders for additive manufacturing and industrial 3D printing, STAUFF offers the possibility to have fully functional prototypes and small series of fastening elements for pipes, tubes, hoses, cables and other components produced – precisely, quickly and at highly economic conditions.

And that's how simple it works:

- Create CAD model in your usual development environment.

- Access stauff.protiq.com.

- Upload the component in any common CAD format.

Your file will be automatically checked and repaired, if necessary. - Adjust the size of the component online, if necessary.

- Select the material, colour and further processing steps.

- Set the desired production time (standard, express, economy).

Immediately after defining all parameters, you will be presented with an quotation price (plus shipping costs) at which you can have the uploaded component manufactured.

Adjust the quantity, if necessary, create a customer account and submit your order. PROTIQ will manufacture your component within the desired production time and ship it to the address you specify. You pay conveniently by invoice after receiving your delivery.

Your Advantages at STAUFF

Strong Partners

Immediate Quotation

Professional Consultation

Production and Delivery

Individual Consultation by STAUFF

You are welcome to take advantage of a free individual consultation with a STAUFF product specialist in advance and have your component checked for suitability for your specific application and optimised, if required. As a market-leading manufacturer of fastening elements for pipes, tubes, hoses, cables and other components, STAUFF is also happy to support you in transferring your prototype to large-batch production.

Materials and Additive Production Process

In accordance with STAUFF components, which are usually manufactured in large batches using injection moulding, the polyamidic plastic PA12 is used as standard in the additive manufacturing of fastening elements for pipes, tubes, hoses, cables and other components, which is processed by PROTIQ using the SLS process (selective laser sintering).

Polyamidic Plastic PA12

The material PA12 (PA 2200 based on polyamide 12) is cost-effective, can be processed with a high degree of accuracy and is suitable for mechanically loaded functional prototypes and small batches. It is often used as a direct alternative to plastics that are processed by injection moulding. Among other things, it is chemically resistant to elements such as oil, fuels, hydraulic fluids, grease, salt, solvents and water. PA12 also impresses with noise and vibration damping properties, good heat resistance and high abrasion resistance.

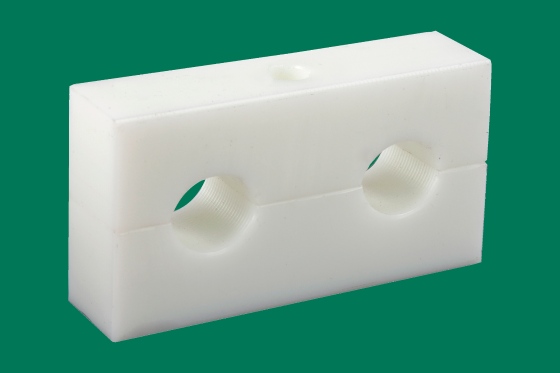

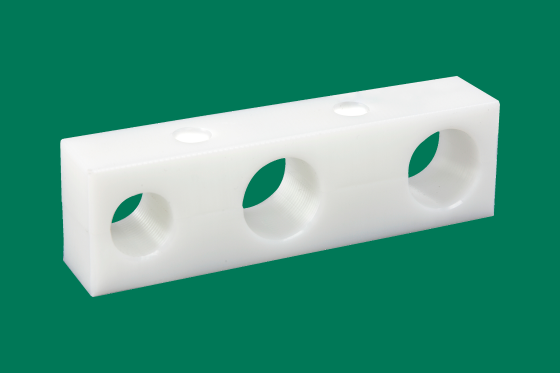

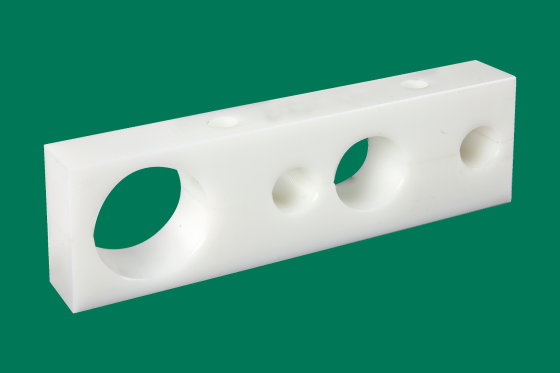

The basic colour of PA12 is white.

Colouring in various standard colours by painting or dip coating is possible on request.

Selective Laser Sintering (SLS)

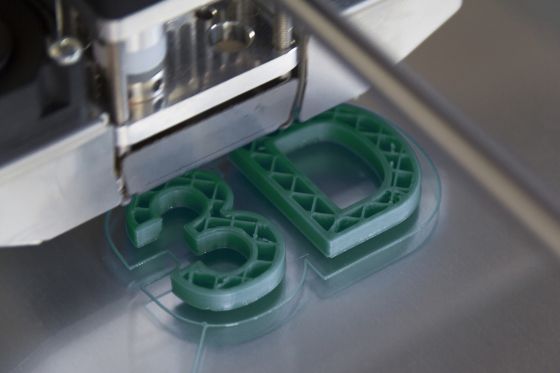

Selective Laser Sintering (SLS) is a 3D printing process that uses laser radiation as an energy source to make 3D objects out of plastic. In the first step, a thin layer of powder is applied to the build platform using a squeegee, a combination of several squeegees, or a roller. The layer thicknesses range from 0.05 mm to 0.15 mm, depending on the resolution and installation. After the powder is applied uniformly, the construction chamber is heated to just below the melting range of the respective plastic and melted locally by a laser at the points where the component is to be formed. Subsequently, the build platform lowers by one layer of thickness and the process begins anew. The process repeats until the last layer of the 3D model has been printed.

Application Examples for Fastening Elements

Using industrial 3D printing, STAUFF and PROTIQ produce fully functional and durable components for the secure fastening of pipes, tubes, hoses, cables and other components in hydraulics and other industrial applications.

Polyamidic materials in the basic colour white are generally used. Colouring in various standard colours by painting or dip coating is possible on request.

The additive manufacturing process enables the production of prototypes and components in small batches at extremely economical conditions and fast delivery times.

There are virtually no limits to the design of the parts: Most of the products are pipe clamps, tube clamps, hose clamps and cable clamps in block form (consisting of two identical clamp halves) for fastening two or more individual lines. However, more complex multi-part solutions can also be easily implemented in industrial 3D printing.