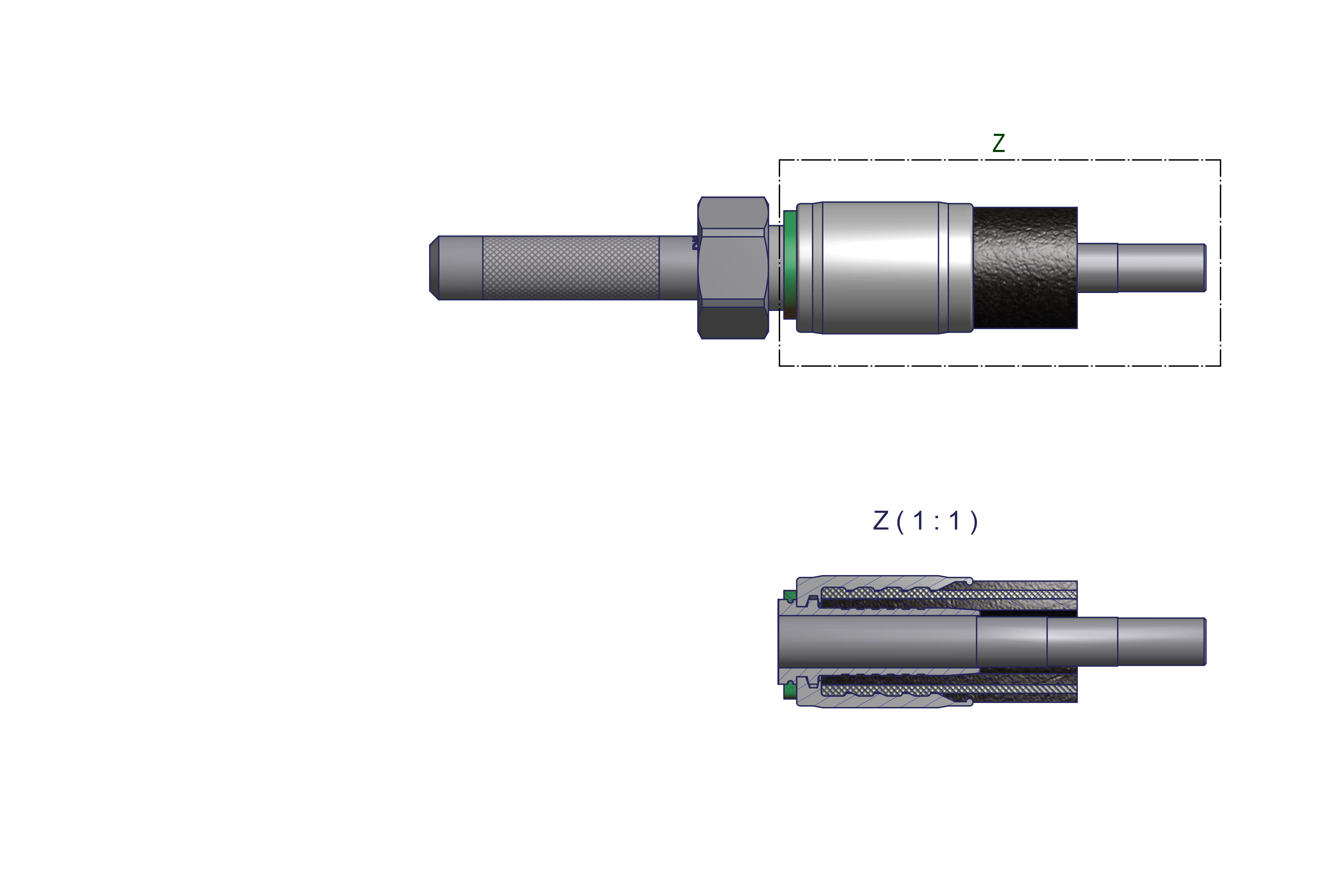

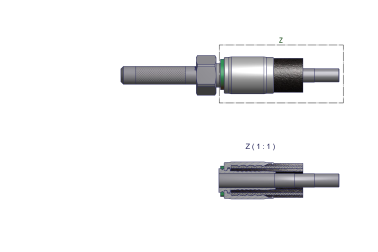

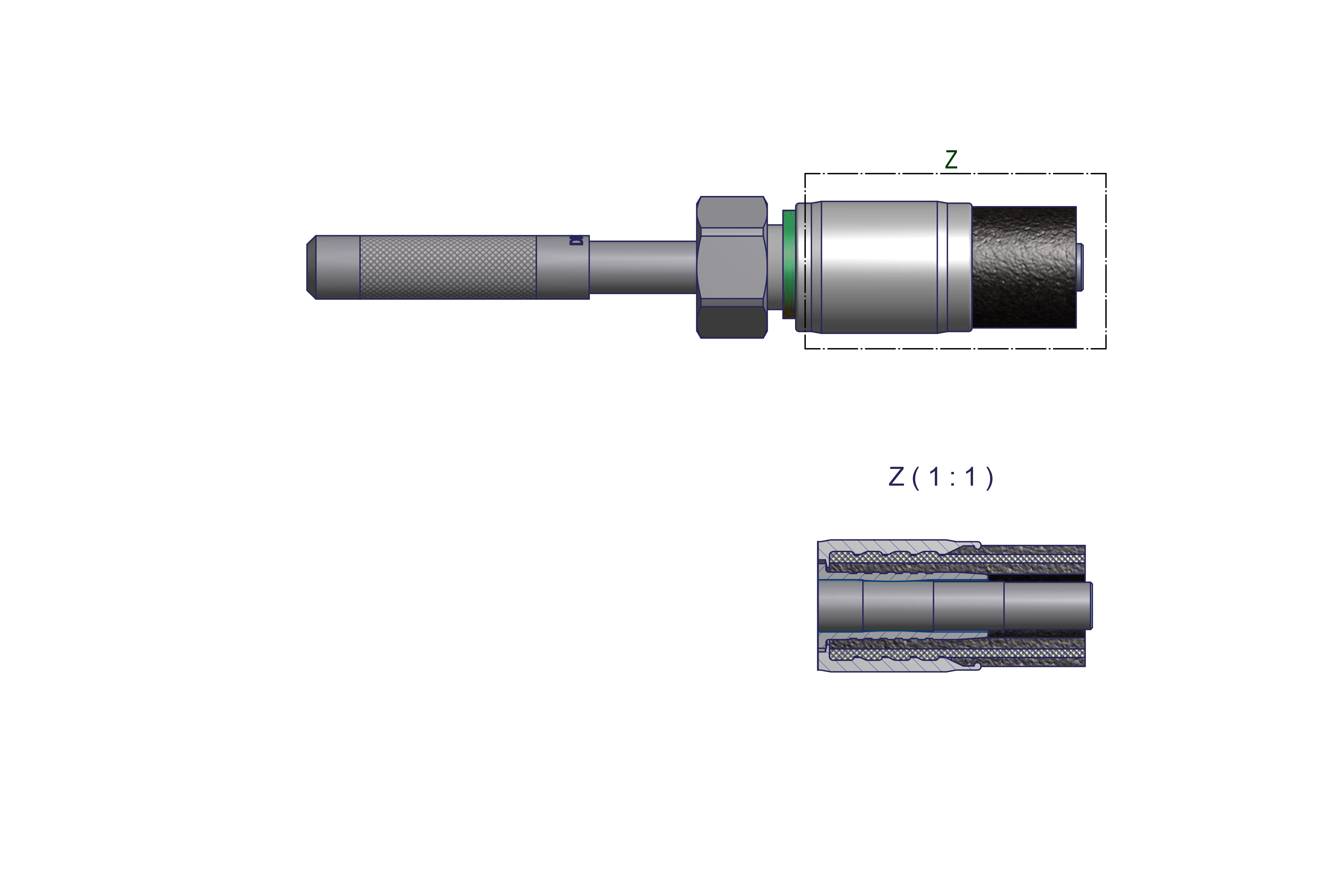

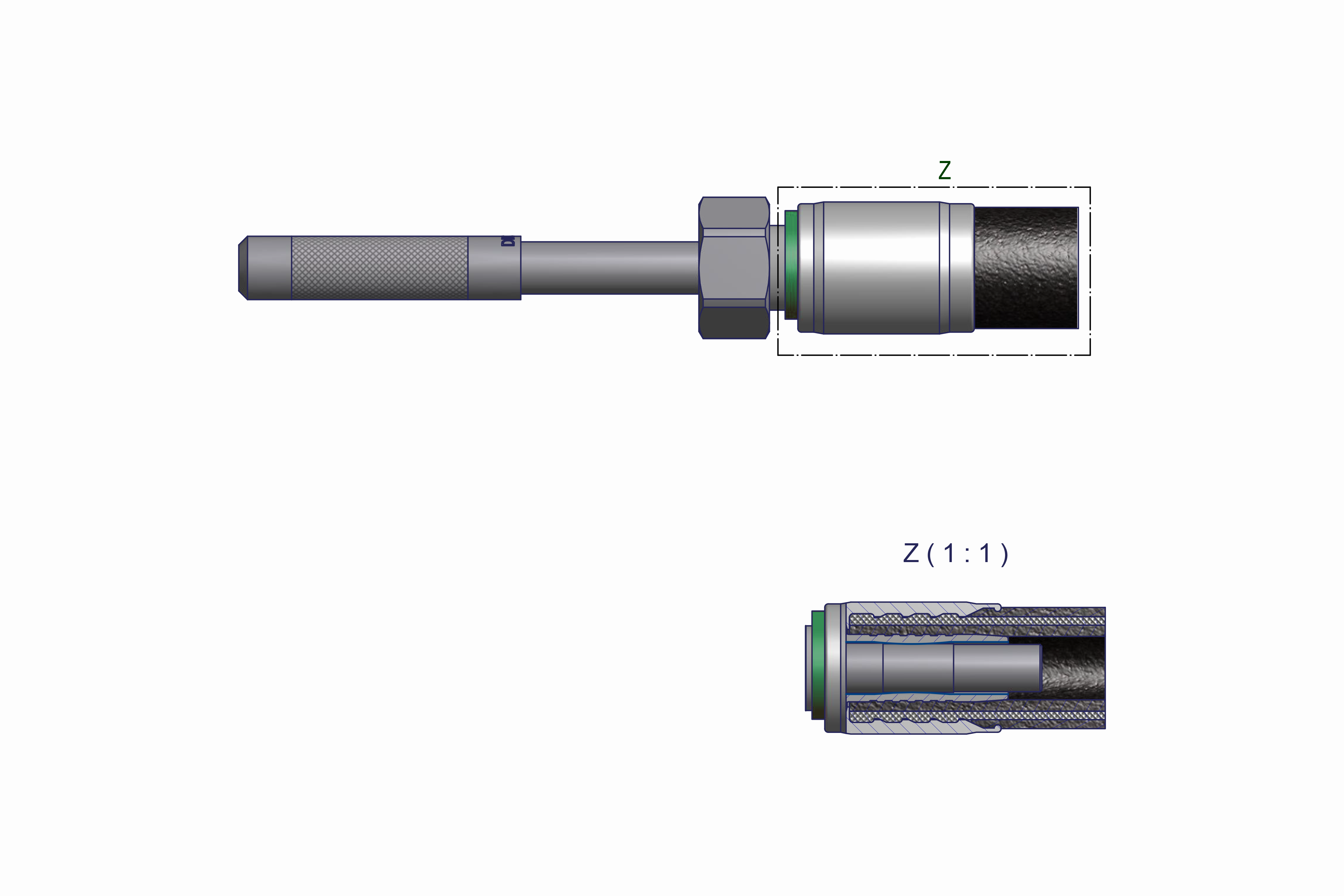

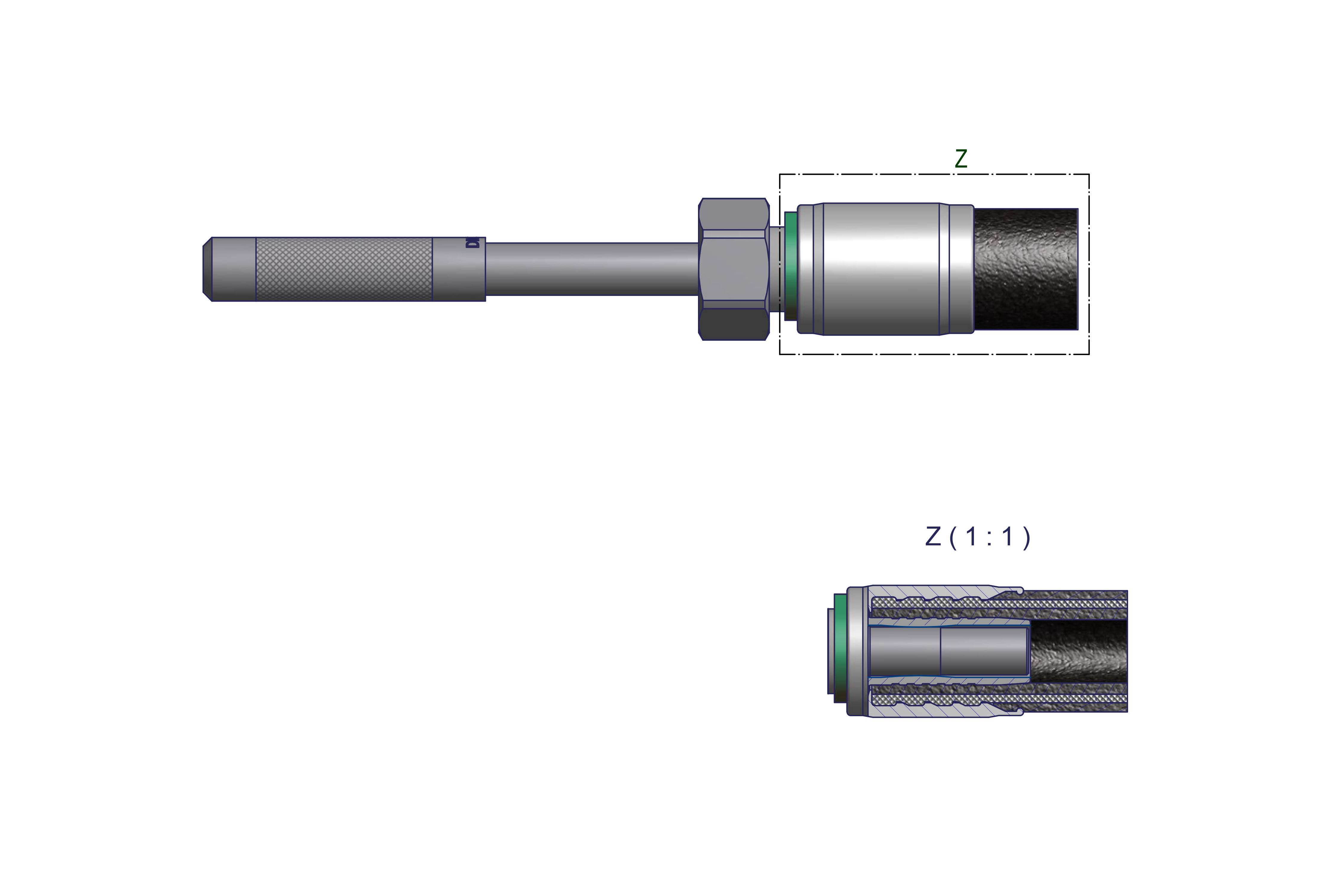

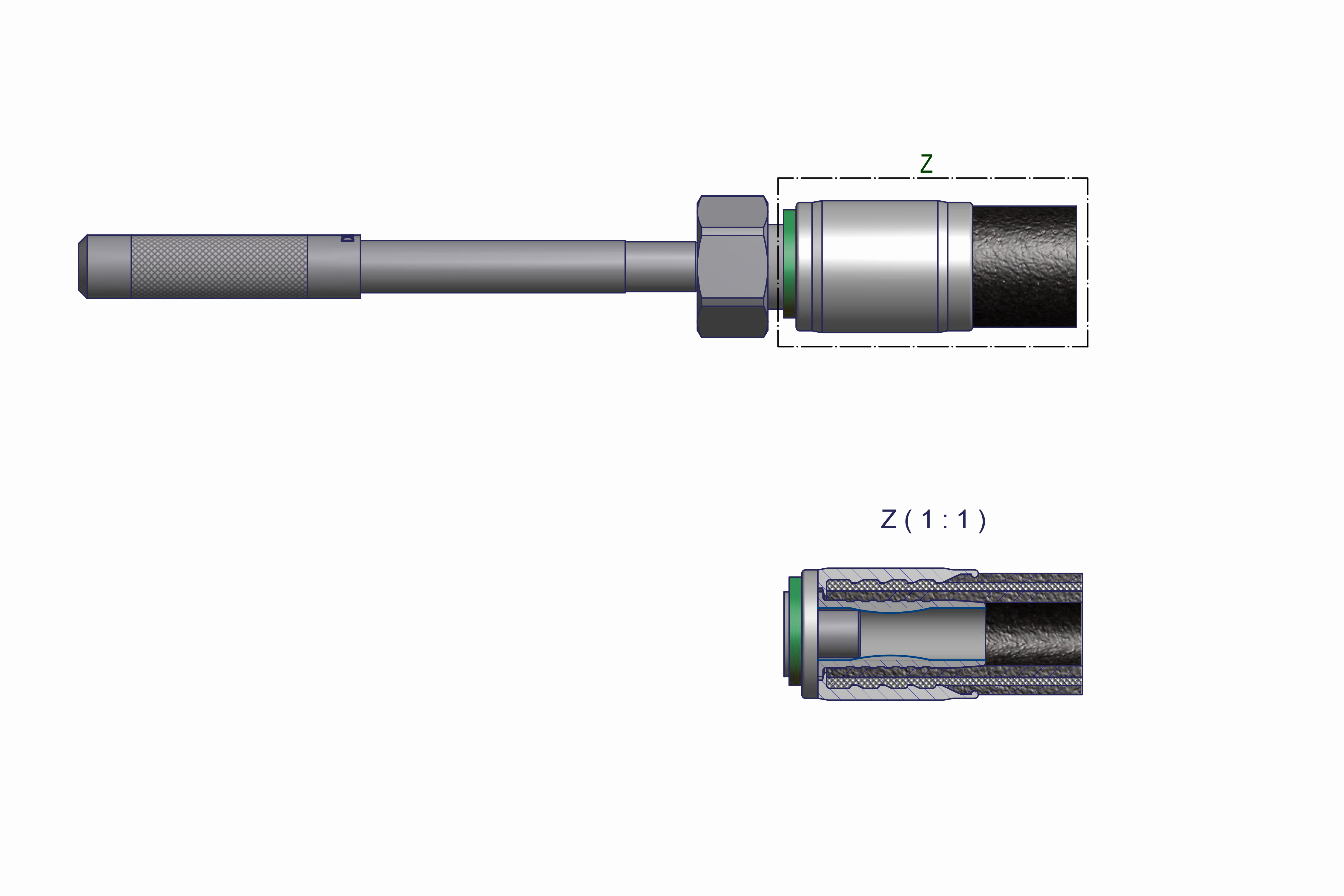

No nipple collapse was created by pressing. Press dimension is too large.

ATTENTION: The connection is not functional. Leakage and risk of the hose slipping out of the crimped fitting

from the crimped fitting. The crimping diameter must be reduced by a few tenths of a mm!