What is it all about?

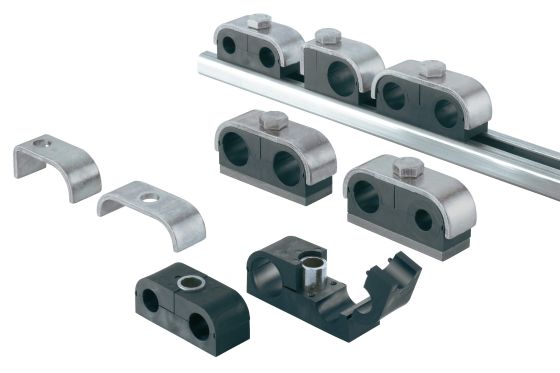

In industry, there is rarely a universal solution that satisfies all customers and users equally. This is also reflected in the development of our STAUFF LBBU clamps. These lightweight clamps are often used in mobile hydraulics, e.g. on small construction and agricultural machinery, and in industrial plant engineering. They offer an uncomplicated way of clamping and securely fastening cables.

As a customer-orientated company, we have made various adaptations in recent years in order to find the optimum solution for different requirements. A look back at the development of our LBBU clamps and a look into the future.

The challenge: ease of installation vs. durability

Our LBBU clamps were originally developed as an alternative to the solutions previously available on the market. The clamp bodies are made of slotted rubber so that cables can be clamped relatively easily. However, depending on the size and material hardness, this installation proved to be challenging.

To reduce the assembly effort, we introduced our LBBU variant with a film hinge in 2008. The "cover" of the clamp can be folded away to the side, which significantly reduces the amount of force required to insert the cable. This technological innovation made installation considerably easier.

Customer-centred further development: a dynamic process

Not all users were ready to switch from the slotted version to the film hinge; some continued to insist on the classic slotted version. In 2021, we therefore decided to gradually switch back to the slotted version that is well-known and established on the market - but only for certain sizes and depending on necessary tool updates.

However, the market continues to develop and in 2024 it became clear that demand for the film hinge version is growing again. Our customers have signalled to us that they appreciate the simple assembly of this variant. That is why we are now returning to the film hinge solution for all sizes. We are actively supporting this changeover with clear communication to the customers concerned.

The balance between standardisation and individuality

Our conclusion: there is no such thing as a perfect one-size-fits-all solution. Our old/new standard across all sizes will once again be the film hinge variant. At the same time, we remain flexible and continue to offer slotted versions for customers with special requirements - especially for large quantities. We will also continue to offer an optional version for M8 screws, as favoured in the heavy-duty sector.

Our promise: Solutions that go beyond the market standard

These developments underline our claim to offer not only market-driven but also customised solutions. STAUFF listens, analyses requirements and implements adaptations - always with the aim of providing our customers with the best possible support. For us, innovation not only means new products, but also the ability to respond flexibly to our customers' wishes.

FAQs

Why was the film hinge variant originally chosen?

Why did you switch back to the slotted version in 2021?

Some customers were not prepared to switch from the tried-and-tested slotted version to the clamps with a film hinge. As these customers outnumbered us in 2021, we decided to switch the standard for designs 2 and 2D to the slotted version.

Why is STAUFF returning to the film hinge variant in 2025?

It turned out that many customers prefer the simple assembly of the film hinge version. Due to the increased demand, we have decided to re-establish this variant as the standard.

Will the slotted version still be offered?

Yes, we will continue to offer the slotted version for customers with special requirements - especially for large customers with corresponding purchase quantities.

What variants are available for the screws?

We offer LBBU clamps for both M6 (standard) and M8 (heavy duty) screws. Variants with imperial screws are also available.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog